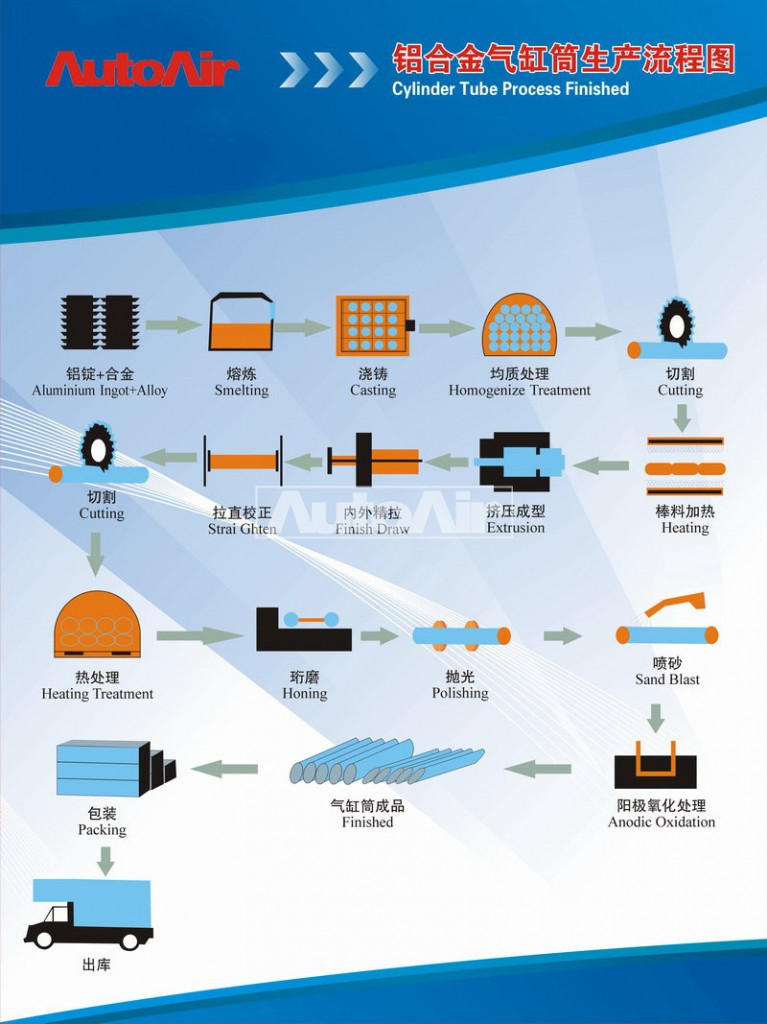

Cov txheej txheem ntau lawm ntawm pneumatic lub tog raj kheej raj

Raw Material Rhiav

Raw Material Rhiav

Extrusion Rhiav

Extrusion Rhiav

Ua kom tiav Draw Rhiav

Ua kom tiav Draw Rhiav

Honing Rhiav

Honing Rhiav

Polishing Rhiav

Polishing Rhiav

Sand Blast Rhiav

Sand Blast Rhiav

Anodic Oxidation Rhiav

Anodic Oxidation Rhiav

Packing Pneumatic lub tog raj kheej Tube

Packing Pneumatic lub tog raj kheej Tube

Npaj khoom rhiav

Npaj khoom rhiav

Ua ntej tshaj plaws, tom qab tau txais cov neeg siv khoom kos duab kos duab lossis cov neeg siv khoom siv peb cov qauv kos duab, peb yuav yuav cov khoom siv raw rau pwm qhib.

Kauj ruam 1:Extruded Aluminium profile raws li kev kos duab los ntawm pwm

2 teeb ntawm hnyav-duty aluminium profile extrusion tshuab

Kauj ruam 2:Kos tag

Kauj Ruam 3:Ncaj

Kauj Ruam 4:Txiav

Kauj ruam 5:Kev kho cua sov

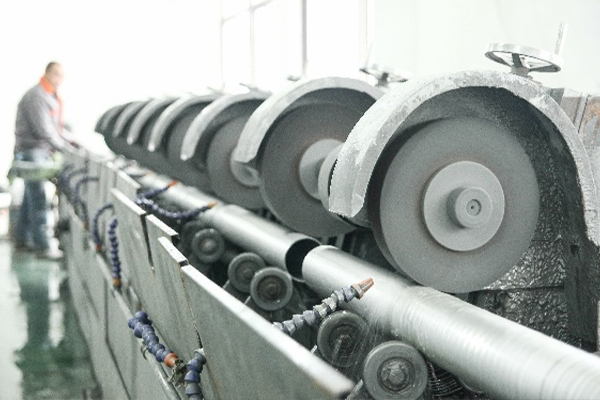

Kauj Ruam 6:Honing

12 teeb ntawm Pneumatic lub tog raj kheej raj honing tshuab

FAQ:

Q1: Lub honing yog dab tsi?

A: Kev ua tiav ntawm qhov chaw tiav nrog whetstone (tseem hu ua honing stick) kos rau hauv lub taub hau honing.Kuj hu ua tho txawv.Nws tsuas yog ua ntau yam cylindrical qhov nrog ib txoj kab uas hla ntawm 5 mus rau 500 mm lossis loj dua, thiab qhov sib piv ntawm lub qhov tob rau lub qhov taub tuaj yeem ncav cuag 10 lossis ntau dua.Nyob rau hauv tej yam kev mob, nws tseem tuaj yeem ua cov dav hlau, qhov chaw sab nraud, lub ntsej muag kheej kheej, cov hniav hniav, thiab lwm yam. Lub voj voog sab nrauv ntawm lub taub hau honing yog inlaid nrog 2-10 whetstones nrog ntev li ntawm 1/3 txog 3/4 ntawm qhov ntev.Thaum honing lub qhov, nws tig thiab txav rov qab thiab tawm mus.Nyob rau tib lub sijhawm, nws nthuav dav sib npaug los ntawm lub caij nplooj ntoos hlav lossis hydraulic tswj hauv lub taub hau honing.Yog li ntawd, qhov chaw sib cuag nrog qhov chaw ntawm lub qhov yog loj dua, thiab kev ua haujlwm zoo dua.Qhov tseeb qhov tseeb ntawm lub qhov tom qab honing yog IT7 ~ 4, thiab qhov chaw roughness tuaj yeem ncav cuag Ra0.32 ~ 0.04 microns.Qhov loj ntawm qhov nyiaj pub dawb nyob ntawm lub qhov taub thiab cov khoom siv ntawm cov khoom ua haujlwm, feem ntau 0.02 ~ 0.15 hli rau cov hlau cam khwb cia thiab 0.01 ~ 0.05 hli rau steel qhov chaw.Kev sib hloov ceev ntawm lub taub hau honing feem ntau yog 100 ~ 200 rpm, thiab qhov ceev ntawm lub reciprocating txav feem ntau yog 15 ~ 20 m / min.Txhawm rau tshem tawm cov txiav txiav thiab cov khoom abrasive, txhim kho qhov roughness ntawm qhov chaw thiab txo qhov kub ntawm qhov txiav, qhov loj ntawm cov kua txiav, xws li roj av lossis cov roj me me, feem ntau siv thaum lub sijhawm ua haujlwm, thiab Qee zaum kuj siv cov emulsion siab heev.

Kauj Ruam 7:Polishing

2 txheej ntawm nto polishing tshuab

Kauj Ruam 8:Xuab zeb tawg

2 txheej ntawm nto sandblasting tshuab

FAQ

Q1: Lub tshuab xuab zeb yog dab tsi?

A: Cov txheej txheem ntawm kev siv cov kev cuam tshuam ntawm high-ceev xuab zeb ntws los ntxuav thiab roughen saum npoo ntawm substrate.Cov cua compressed yog siv los ua lub zog los tsim lub dav hlau dav hlau ceev kom txau cov khoom siv tshuaj tsuag (tooj liab ore, quartz xuab zeb, emery xuab zeb, hlau xuab zeb, Hainan xuab zeb) ntawm kev kub ceev mus rau saum npoo ntawm lub workpiece yuav tsum tau kho, yog li ntawd. Lub ntsej muag lossis cov duab ntawm lub ntsej muag ntawm qhov chaw ua haujlwm tau hloov pauv, Vim tias muaj kev cuam tshuam thiab txiav kev txiav txim siab ntawm abrasive ntawm qhov chaw ua haujlwm, qhov chaw ntawm lub workpiece tuaj yeem tau txais qee qhov kev huv huv thiab qhov sib txawv ntawm qhov sib txawv, yog li ntawd. Cov khoom siv ntawm qhov chaw ua haujlwm tau zoo dua qub, yog li txhim kho qhov qaug zog ntawm cov khoom ua haujlwm, thiab ua rau nws thiab txheej txheej Cov adhesion ntawm cov khaubncaws sab nraud povtseg ncua lub durability ntawm txheej zaj duab xis, thiab kuj yog conducive rau leveling thiab kho kom zoo nkauj ntawm txheej.

Kauj Ruam 9:Anodizing

2 txheej ntawm anodizing kho kab

FAQ:

Q1: Dab tsi yog anodizing?

A: Anodic oxidation, electrochemical oxidation ntawm hlau los yog alloys.Aluminium thiab nws cov alloys tsim ib txheej ntawm oxide zaj duab xis ntawm cov khoom siv txhuas (anode) nyob rau hauv qhov kev txiav txim ntawm kev siv tam sim no raws li cov khoom siv electrolyte thiab cov txheej txheem tshwj xeeb.Yog tias anodizing tsis tau teev tseg, nws feem ntau yog hais txog sulfuric acid anodizing.

Txhawm rau kov yeej qhov tsis xws ntawm aluminium alloy nto hardness, hnav tsis kam thiab lwm yam, nthuav dav ntawm daim ntawv thov, thiab txuas ntxiv lub neej kev pabcuam, kev kho tshuab saum npoo tau dhau los ua ib feem tseem ceeb ntawm kev siv aluminium alloy, thiab anodizing technology yog tam sim no. qhov feem ntau siv thiab ua tiav ntawm.

Kauj ruam 10:Ua tiav aluminium cylinder raj

Kauj Ruam 11:Aluminium lub tog raj kheej raj packing