304 Stainless Hlau Pneumatic Lub tog raj kheej Piston Qws, Stainless Hlau Ncej

Qhia

Cov pas nrig ua ntej dhau los ua qhov tseeb milling thiab ua tiav, thiab tom qab ntawd muab tso rau hauv kev kho deg chromium, tso cai rau saum npoo ntawm f8, thiab qhov tawv tawv ncav cuag HV850 yam tsawg kawg nkaus thiab nce, uas tsis yog tsuas yog pab txhim kho kev hnav tsis kam, tab sis kuj pab txuas ntxiv. lub neej voj voog ntawm cov pas nrig, yog li pab cov neeg siv khoom txuag nqi.

Daim ntawv thov

Ncaj nraim rau lub tog raj kheej, lub tog raj kheej, kev poob siab absorber piston pas nrig, thiab yog dav siv nyob rau hauv textile printing thiab dyeing, luam ntawv machinery, qhia rail, tuag-casting tshuab, txhaj molding tshuab qhia qws, ejector thiab lwm yam khoom siv kho tshuab ntawm phau ntawv pin thiab plaub- kem xovxwm qhia ncej, fax tshuab, tshuab luam ntawv thiab lwm yam niaj hnub chaw ua hauj lwm machinery qhia ncej thiab ib co precision slender ncej rau cov khoom lag luam khoom.

Khoom Paub meej

| specifications | φ6-φ12 | φ16-φ25 | φ30-φ50 | φ55-φ100 | φ105-φ1200 |

| ntev | 200-2000 | 200-3000 | 200-5000 | 200-10000 | 1000-10000 |

| Nto roughness | Ra<0.2 | ||||

| Kev kho deg ntawm hardness | HRC6 | Kev ncaj | 0.15 / 1000mm | ||

| Circle of Tolerance | wb 11849Qib | Chrome thickness | Raws li cov neeg siv khoom xav tau | ||

| Full-length size Tolerance | GB1100 TSIQib | Khoom siv | Raws li cov neeg siv khoom xav tau | ||

| Axis ntawm hardness | HB220-280 | ||||

| Muaj xwm txheej | Tsis muaj kev kho deg, chrome lossis npib tsib xee-phosphorus plating ntawm qhov chaw, ntsev tsuag nitriding rau saum npoo | ||||

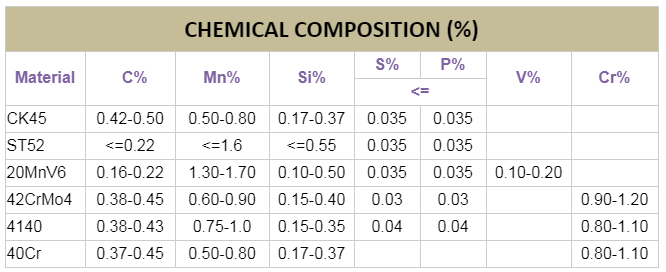

| CHEMICAL COMPOSITION(%) | |||||||

| Khoom siv | C% | Mn% | Si% | S% | P% | V% | Cr% |

| <= | |||||||

| CK45 | 0.42-0.50 Nws | 0.50-0.80 Nws | 0.17-0.37 Nws | 0.035 ib | 0.035 ib | ||

| TSI 52 | <=0.22 | <=1.6 | <=0.55 | 0.035 ib | 0.035 ib | 0.10-0.20 Nws | |

| 20mnv 6 | 0.16-0.22 dr hab | 1.30-1.70 Nws | 0.1-0.50 Nws | 0.035 ib | 0.035 ib | ||

| 42CrMo4 | 0.38-0.45 Nws | 0.60-0.90 Nws | 0.15-0.40 Nws | 0.03 ib | 0.03 ib | 0.90-1.20 Nws | |

| 4 140 | 0.38-0.43 Nws | 0.75-1.0 Nws | 0.15-0.35 dr hab | 0.04 ib | 0.04 ib | 0.80-1.10 Nws | |

| 40 Cr | 0.37-0.45 dr hab | 0.50-0.80 Nws | 0.17-0.37 Nws | 0.80-1.10 Nws | |||

| Txoj kab uas hla | Qhov hnyav | Ua siab ntev | Ua siab ntev | Ua siab ntev |

| mm | Kg / m | f7m (nqi) | f8 (m) | h6 (μm) |

| ¢ 6 | 0.22 | -10--22 | -10--28 | 0--9 |

| ¢8 | 0.39 ib | -13-28 | -13-35 | 0--9 |

| ¢ 10 | 0.62 ib | -13-28 | -13-35 | 0--11 |

| ¢ 12 | 0.89 ib | -16-34 | -16-43 | 0--11 |

| ¢ 16 | 1.58 ib | -16-34 | -16-43 | 0--11 |

| ¢ 18 | 2.00 Nws | -16-34 | -16-43 | 0--13 |

| ¢ 20 | 2.47 ib | -20--41 | -20--53 | 0--13 |

| ¢ 22 | 2.99 ib | -20--41 | -20--53 | 0--13 |

| ¢ 25 | 3.86 ib | -20--41 | -20--53 | 0--13 |

| ¢ 28 | 4.84 ib | -20--41 | -20--53 | 0--13 |

| ¢ 30 | 5.55 ib | -20--41 | -20--53 | 0—16 |

| ¢ 32 | 6.32 ib | -25--50 | -25-64 | 0—16 |

| ¢ 36 | 8.00 Nws | -25--50 | -25-64 | 0—16 |

| ¢ 38 | 8.91 ib | -25--50 | -25-64 | 0—16 |

| ¢ 40 | 9.87 ib | -25--50 | -25-64 | 0—16 |

Chemical composition table

FAQ:

Q1: Dab tsi yog stainless hlau pneumatic lub tog raj kheej nyuaj chrome rods?

A: Stainless hlau nyuaj chrome pas nrig yog siv rau hydraulic thiab pneumatic piston rods rau engineering machinery, tsheb tsim, qhia posts rau yas machinery, rollers rau ntim machinery, luam ntawv machinery, textile machinery, axis rau conveying machinery, thiab linear optical axis rau linear zog..Lub piston pas nrig yog ua tiav los ntawm dov.Vim tias cov txheej txheej saum npoo muaj qhov seem ntawm qhov kev ntxhov siab, nws pab kaw cov kab nrib pleb ntawm qhov chaw thiab cuam tshuam qhov nthuav dav ntawm corrosion.

Q2: Dab tsi yog cov yam ntxwv ntawm stainless hlau pneumatic lub tog raj kheej piston pas nrig?

A: Stainless hlau pneumatic lub tog raj kheej piston pas nrig yog ua tiav los ntawm dov.Vim tias cov txheej txheej saum npoo muaj qhov seem ntawm qhov kev ntxhov siab, nws yuav pab kom kaw qhov chaw micro tawg thiab cuam tshuam qhov nthuav dav ntawm corrosion.

Li no txhim kho qhov chaw corrosion kuj, thiab tuaj yeem ncua kev tsim lossis nthuav tawm ntawm kev qaug zog tawg, yog li txhim kho lub zog qaug zog ntawm lub tog raj kheej pas nrig.Los ntawm yob txoj kev, txheej txheej ua haujlwm txias yog tsim rau ntawm qhov chaw dov, uas txo cov elastic thiab yas deformation ntawm kev sib cuag ntawm cov khub sib tsoo, yog li txhim kho qhov hnav tsis kam ntawm lub tog raj kheej pas nrig nto thiab tsis txhob hlawv los ntawm kev sib tsoo.Tom qab dov, tus nqi deg roughness yog txo, uas tuaj yeem txhim kho cov khoom sib txuas.Nyob rau tib lub sijhawm, kev sib txhuam kev puas tsuaj rau lub nplhaib sib khi lossis cov khoom sib khi thaum lub sij hawm txav ntawm lub tog raj kheej pas nrig piston raug txo, thiab tag nrho cov kev pab cuam lub neej ntawm lub tog raj kheej pneumatic yog txhim kho.

Q3: Dab tsi yog qhov zoo ntawm 304 stainless hlau piston pas nrig

A: Stainless hlau 304 yog cov khoom siv hauv kev tsim cov piston pas nrig.Nws yog resistant rau tsis muaj zog corrosive media xws li huab cua, chav, thiab dej.Cov ntaub ntawv siv feem ntau yog 304, 316. Lub weldability, polishability, kub tsis kam, corrosion kuj, thiab corrosion kuj ntawm cov ntaub ntawv no kuj zoo.Los ntawm kev ua kom txias txias, kev sib tsoo, kev ua haujlwm siab polishing thiab lwm yam txheej txheem, stainless hlau piston pas nrig tsim los ntawm Tag nrho cov kev qhia ua tau raws li lub teb chaws tus qauv, yog li lawv feem ntau siv hauv cov roj thooj voos kheej kheej, lub tog raj kheej cua, thiab kev poob siab absorbers.

Q4: Dab tsi yog cov txheej txheem dov ntawm stainless hlau pneumatic lub tog raj kheej piston pas nrig?

A: Lub piston pas nrig ntawm stainless hlau pneumatic lub tog raj kheej yog ua tiav los ntawm dov.Vim tias cov txheej txheej saum npoo muaj qhov seem ntawm qhov kev ntxhov siab, nws yuav pab kom kaw qhov chaw micro tawg thiab cuam tshuam qhov nthuav dav ntawm corrosion.

Li no txhim kho qhov chaw corrosion kuj, thiab tuaj yeem ncua kev tsim lossis nthuav tawm ntawm kev qaug zog tawg, yog li txhim kho lub zog qaug zog ntawm lub tog raj kheej pas nrig.Los ntawm yob txoj kev, txheej txheej ua haujlwm txias yog tsim rau ntawm qhov chaw dov, uas txo cov elastic thiab yas deformation ntawm kev sib cuag ntawm cov khub sib tsoo, yog li txhim kho qhov hnav tsis kam ntawm lub tog raj kheej pas nrig nto thiab tsis txhob hlawv los ntawm kev sib tsoo.Tom qab dov, tus nqi deg roughness yog txo, uas tuaj yeem txhim kho cov khoom sib txuas.Nyob rau tib lub sijhawm, kev sib txhuam kev puas tsuaj rau lub nplhaib sib khi lossis cov khoom sib khi thaum lub sij hawm txav ntawm lub tog raj kheej pas nrig piston raug txo, thiab tag nrho cov kev pab cuam lub neej ntawm lub tog raj kheej pneumatic yog txhim kho.

Q5: Dab tsi yog cov yam ntxwv ntawm stainless hlau piston pas nrig ntawm lub tog raj kheej pneumatic?

A: 1.Excellent corrosion kuj, zoo corrosion kuj nyob rau hauv cov txheej txheem ntau lawm ntawm pulp thiab ntawv.Ntxiv mus, 304 stainless hlau kuj tseem tiv taus corrosion los ntawm dej hiav txwv thiab corrosive industrial cua.

2. Nyob rau hauv qhov kub thiab txias ib puag ncig, 304 stainless hlau muaj oxidation zoo.Nyob rau hauv qhov kub thiab txias, thaum lub concentration ntawm sulfuric acid qis dua 15% thiab siab dua 85%, 304 stainless hlau muaj ntau yam kev siv.