S45C Hard Chrome Plated Piston Qws Rau Pneumatic Lub tog raj kheej

Lub pneumatic lub tog raj kheej hydraulic piston pas nrig kuj hu ua chrome-plated pas nrig.Nws yog ib tug pas nrig nrog ib tug nto kho los ntawm kev sib tsoo tshwj xeeb thiab nyuaj chrome plating.Nws yog dav siv nyob rau hauv ntau lub tog raj kheej, hydraulic kheej kheej, ntim, woodworking, spinning, luam ntawv thiab dyeing tshuab, tuag-casting qhov chaw thiab lwm yam tsis siv neeg kis tau tus mob li vim nws hardness, uas muaj peev xwm ntev lub neej kev pab cuam ntawm zoo tib yam precision machinery thiab khoom.

Peb tau txais kev txiav txim siab txias txias, honing thiab polishing los tsim cov pneumatic lub tog raj kheej hydraulic piston pas nrig, txhua lub hom phiaj kev ua tau raws li lub teb chaws tus qauv.

Paub meej Specification

Khoom siv: CK45 (GB / T699-1999)

Mechanical specification:

Tensile zog (Mpa): ≥600N / mm2

0.2 Yield Stress (Mpa): ≥355N / mm2

Elongation: min.16%

Chrome Plated Thickness: φ20mm ≥15μm, los ntawm φ20mm ~ 20μm

Roughness: Ra < 0.2

Hardness Chrome Txheej: 850HV-1050HV

Txoj kab uas hla: f7,f8

Ncaj: <0.1um / 1000mm

Ovality: < 1/2 txoj kab uas hla

Kev ntsuam xyuas Corroseston Test: ISO 10289: 1999, IDT

Sab nraud txoj kab uas hla: 3-120mm (GCr15) 3-40m (SUS440C)

Cov xwm txheej ntawm tus me nyuam: Ib txwm, Induction Harden, Q + T

Chemical composition table

| CHEMICAL COMPOSITION(%) | |||||||

| Khoom siv | C% | Mn% | Si% | S% | P% | V% | Cr% |

| <= | |||||||

| CK45 | 0.42-0.50 Nws | 0.50-0.80 Nws | 0.17-0.37 Nws | 0.035 ib | 0.035 ib | ||

| TSI 52 | <=0.22 | <=1.6 | <=0.55 | 0.035 ib | 0.035 ib | 0.10-0.20 Nws | |

| 20mnv 6 | 0.16-0.22 dr hab | 1.30-1.70 Nws | 0.1-0.50 Nws | 0.035 ib | 0.035 ib | ||

| 42CrMo4 | 0.38-0.45 Nws | 0.60-0.90 Nws | 0.15-0.40 Nws | 0.03 ib | 0.03 ib | 0.90-1.20 Nws | |

| 4 140 | 0.38-0.43 Nws | 0.75-1.0 Nws | 0.15-0.35 dr hab | 0.04 ib | 0.04 ib | 0.80-1.10 Nws | |

| 40 Cr | 0.37-0.45 dr hab | 0.50-0.80 Nws | 0.17-0.37 Nws | 0.80-1.10 Nws | |||

| Txoj kab uas hla | Qhov hnyav | Ua siab ntev | Ua siab ntev | Ua siab ntev |

| mm | Kg / m | f7m (nqi) | f8 (m) | h6 (μm) |

| 6 | 0.22 | -10--22 | -10--28 | 0--9 |

| 8 | 0.39 ib | -13-28 | -13-35 | 0--9 |

| 10 | 0.62 ib | -13-28 | -13-35 | 0--11 |

| 12 | 0.89 ib | -16-34 | -16-43 | 0--11 |

| 16 | 1.58 ib | -16-34 | -16-43 | 0--11 |

| 18 | 2.00 Nws | -16-34 | -16-43 | 0--13 |

| 20 | 2.47 ib | -20--41 | -20--53 | 0--13 |

| 22 | 2.99 ib | -20--41 | -20--53 | 0--13 |

| 25 | 3.86 ib | -20--41 | -20--53 | 0--13 |

| 28 | 4.84 ib | -20--41 | -20--53 | 0--13 |

| 30 | 5.55 ib | -20--41 | -20--53 | 0—16 |

| 32 | 6.32 ib | -25--50 | -25-64 | 0—16 |

| 36 | 8.00 Nws | -25--50 | -25-64 | 0—16 |

| 38 | 8.91 ib | -25--50 | -25-64 | 0—16 |

| 40 | 9.87 ib | -25--50 | -25-64 | 0—16 |

| 45 | 12.49 Nws | -25--50 | -25-64 | 0—16 |

| 50 | 14.22 Nws | -25--50 | -25-64 | 0-19 ib |

| 55 | 15.43 Nws | -30-60 | -30-76 | 0-19 ib |

| 60 | 18.66 Nws | -30-60 | -30-76 | 0-19 ib |

| 65 | 26.07 Nws | -30-60 | -30-76 | 0-19 ib |

| 70 | 30.23 Nws | -30-60 | -30-76 | 0-19 ib |

| 75 | 34.71 ib | -30-60 | -30-76 | 0-19 ib |

| 80 | 39.49 Nws | -30-60 | -30-76 | 0—22 ib |

| 85 | 44.58 ib | -36-71 | -36-90 | 0—22 ib |

| 90 | 49.98 ib | -36-71 | -36-90 | 0—22 ib |

| 95 | 55.68 ib | -36-71 | -36-90 | 0—22 ib |

| 100 | 61.70 ib | -36-71 | -36-90 | 0—22 ib |

Dab tsi yog f7 thiab f8 tolerance qauv:

Qhov kev kam rau siab ntawm f8 yog loj dua li ntawm f7, thiab kev teeb tsa nyob ntawm qhov sib txuam qhov kam rau ua cheeb tsam theem.Piv txwv li, thaum qhov loj me me yog 10-18, f8(-0.016,-0.034), f7(-0.016,-0.027), qhov sib txawv ntawm ob qhov kev zam yog tib yam, qhov ntau ntawm f7 yog me dua, thiab qhov clearance ntau yam ntawm lub installation haum yog me dua.

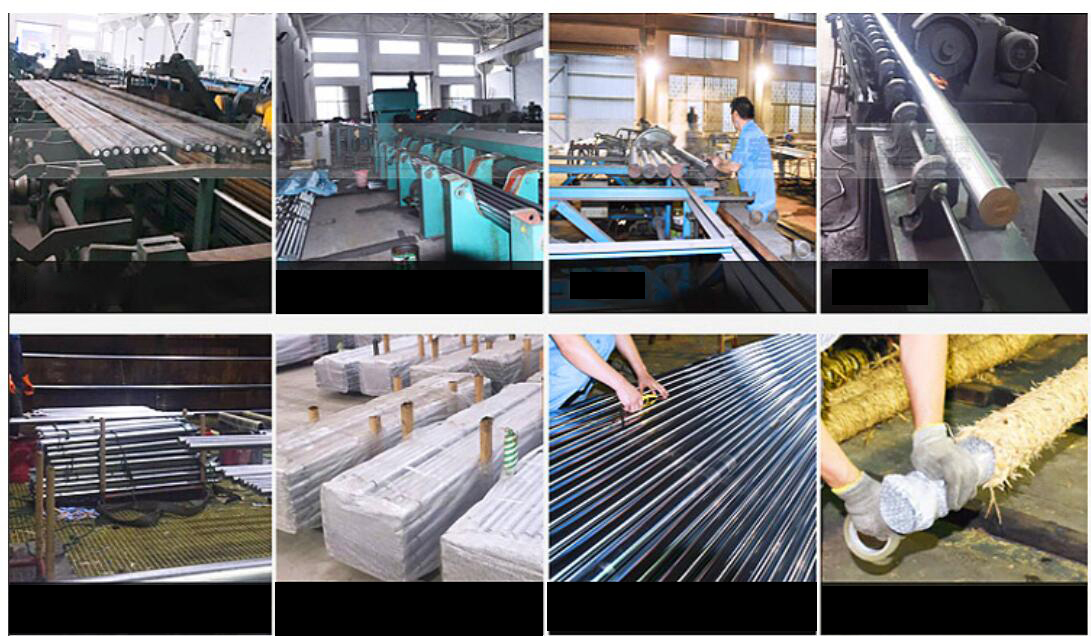

Qhuav Flow

1 Kauj Ruam: Peeling / Cold Drawn:

Kev kos duab txias yog kev ua haujlwm ntawm pneumatic lub tog raj kheej piston pas nrig.Rau pneumatic lub tog raj kheej nyuaj chrome plated pas nrig, cov duab txias yog hais txog kev kos duab nyob rau hauv qhov xwm txheej ntawm qhov kub thiab txias kom ua tiav cov duab thiab qee yam khoom siv kho tshuab.Piv nrog rau kev sib sau kub, cov khoom siv txias txias muaj qhov zoo ntawm qhov raug siab dua qhov tseeb thiab zoo dua qhov chaw tiav.

2 Kauj Ruam: Ncaj

Cov kauj ruam no peb tuaj yeem ua kom lub zog chrome plated pas nrig ncaj txaus.Nws yog ib qho tseem ceeb heev, thaum nruab nws sab hauv lub tog raj kheej pneumatic.Tus qauv ncaj yog 0.2mm / m.

3 Kauj Ruam: Honing

Honing ua yog ib txoj kev ua tau zoo uas ua rau lub tog raj kheej pneumatic piston pas nrig nto kom ua tiav qhov siab, qhov zoo ntawm qhov chaw thiab lub neej ntev.Nws tuaj yeem txhim kho qhov zoo ntawm qhov raug, zoo li qhov tseeb thiab txo tus nqi Ra, tab sis nws tsis tuaj yeem txhim kho txoj haujlwm ntawm lub qhov thiab lwm qhov chaw.

4 Kauj Ruam: Hlau pas nrig Polishing

Polishing hais txog kev siv tshuab, tshuaj lom neeg lossis electrochemical los txo qhov roughness ntawm pneumatic lub tog raj kheej piston pas nrig kom tau txais qhov ci thiab du nto.Nws yog kev siv cov cuab yeej polishing thiab abrasive hais los yog lwm yam xov xwm polishing los hloov kho qhov chaw ntawm lub tog raj kheej pneumatic piston pas nrig

5 Kauj Ruam: Chrome Plating

Chrome plating hais txog kev ua ntawm plating chromium raws li txheej txheej ntawm pneumatic nyuaj chrome plated pas nrig.

Cov txheej txheej chromium-plated muaj qhov tawv tawv heev, thiab nws qhov tawv tawv tuaj yeem sib txawv ntawm ntau yam ntawm 400-1200HV raws li kev sib xyaw ntawm cov tshuaj plating thiab cov txheej txheem txheej txheem.chrome-plated txheej muaj cov cua sov zoo.Thaum rhuab hauv qab 500 ℃, tsis muaj kev hloov pauv hauv gloss thiab hardness.Qhov kub yuav pib oxidize thiab hloov xim thaum kub siab tshaj 500 ℃, thiab hardness yuav txo thaum nws siab tshaj 700 ℃.Kev sib txhuam coefficient ntawm chrome txheej yog me me, tshwj xeeb tshaj yog cov kev sib txhuam qhuav coefficient, uas yog qis tshaj ntawm tag nrho cov hlau.Yog li ntawd, chrome-plated txheej muaj zoo hnav tsis kam.

Cov txheej txheej chromium plating muaj cov tshuaj lom neeg zoo.Nws tsis muaj cov nyhuv alkali, sulfide, nitric acid thiab feem ntau cov organic acids, tab sis nws tuaj yeem yaj hauv pneumatic acid (xws li pneumatic acid) thiab kub sulfuric acid.Nyob rau hauv lub teeb pom kev zoo, qhov kev xav ntawm chromium yog li 65%, uas yog nruab nrab ntawm cov nyiaj (88%) thiab npib tsib xee (55%).Vim tias chromium tsis hloov xim, nws tuaj yeem tswj nws qhov kev xav tau ntev thiab zoo dua li nyiaj thiab npib tsib xee.

6 Kauj Ruam: Chrome plated pas nrig Polishing tom qab plating

Electroplating thiab polishing: yog ob txoj kev sib txawv rau kev kho deg hlau thiab lwm yam ntaub ntawv.Lub qub yog kev kho tshuaj, thiab tom kawg yog kho tshuab.

Electroplating: Cov txheej txheem ntawm kev siv electrolysis los txuas ib txheej ntawm cov yeeb yaj kiab hlau rau saum npoo ntawm cov hlau lossis lwm yam khoom siv.Nws tuaj yeem tiv thaiv corrosion, txhim kho hnav tsis kam, hluav taws xob conductivity, muaj kev cuam tshuam thiab txhim kho kev zoo nkauj.

Polishing: Siv cov cuab yeej polishing hloov tau thiab cov khoom abrasive lossis lwm yam xov xwm polishing los hloov kho qhov chaw ntawm lub workpiece.Polishing tsis tuaj yeem txhim kho qhov tseeb qhov tseeb lossis geometric qhov tseeb ntawm cov khoom ua haujlwm, tab sis lub hom phiaj kom tau txais lub ntsej muag du lossis daim iav gloss.

7 Kauj Ruam: Chrome plated pas nrig Kev Ntsuas Zoo

Piston rods uas tau dhau los ua cov txheej txheem electroplating thiab polishing feem ntau nrog cov txheej txheem xws li chrome pits thiab pitting.Qhov loj thiab qhov ntau ntawm cov teeb meem no cuam tshuam ncaj qha rau kev ua haujlwm ntawm piston pas nrig.Txhawm rau txo qhov cuam tshuam ntawm qhov tsis xws luag ntawm tus pas nrig piston, ntawm ib sab, los ntawm kev txhim kho cov khoom siv raw, txhim kho cov txheej txheem ua haujlwm, thiab txo qhov tshwm sim ntawm qhov tsis xws luag;ntawm qhov tod tes, nws yog ib qho tsim nyog yuav tsum xyuas kom raug plating qhov tsis xws luag tom qab cov txheej txheem polishing kom tsis txhob muaj cov khoom tsis tsim nyog los ntawm kev tawm hauv lub Hoobkas.Autoair's engineers paub txog kev kuaj pom tsis zoo nrog kev paub txog duab science

8 Kauj Ruam: Ntim

FAQ:

Q1: Dab tsi yog pneumatic lub tog raj kheej piston pas nrig?

A: Cov pas nrig piston yog ib qho tseem ceeb thiab tseem ceeb ntawm txhua lub hydraulic lossis pneumatic lub tog raj kheej.Lub piston pas nrig feem ntau yog qhov tseeb machined ntev ntawm cov tawv chrome plated txias tiav steel bar uas xa cov quab yuam tsim los ntawm lub piston mus rau lub tshuab tivthaiv ua haujlwm.

Q2: Lub hauv paus ntsiab lus ntawm pneumatic lub tog raj kheej piston pas nrig yog dab tsi?

A: Lub tog raj kheej pneumatic piston nyob rau hauv lub tog raj kheej bears lub thrust los yog rub quab yuam generated los ntawm huab cua siab, thiab ncaj qha ua rau lub pneumatic lub tog raj kheej piston pas nrig txuas nrog lub piston, thiab ces lub pneumatic lub tog raj kheej piston pas nrig txuas nrog lub load workpiece kom txav. rov qab los.

Q3: Dab tsi yog cov khoom siv raw ntawm koj lub tog raj kheej pneumatic piston pas nrig

A: Feem ntau, lub tog raj kheej pneumatic piston pas nrig ntawm lub tog raj kheej pneumatic yuav xaiv 45 # hlau raws li cov khoom siv raw.Yog tias lub tog raj kheej tsim tau yuav tsum tau siv rau hauv ib puag ncig tshwj xeeb, 304 stainless hlau kuj tuaj yeem siv

Q4: Vim li cas thiaj xaiv 45 # steel li raw khoom

A: 45 # steel yog cov khoom siv zoo carbon steel nrog tsawg hardness thiab yooj yim txiav.Tom qab quenching, nws nto hardness tuaj yeem ncav cuag 45-52HRC.Thiab nws tseem tuaj yeem muaj kev ua haujlwm zoo dua thiab muaj zog dua, toughness thiab lwm yam khoom siv kho tshuab, yog li nws yog ib qho ntawm cov khoom siv feem ntau siv rau cov ncej.

Q5: Dab tsi yog cov txheej txheem machining ntawm koj lub tog raj kheej pneumatic piston pas nrig?

A: Txhawm rau kom tau txais kev ua haujlwm ruaj khov zoo, phau ntawv ncaj qha ntawm tus pas nrig piston tsis raug tso cai tom qab lub tshuab pib.Yog li ntawd, cov txheej txheem straightening yuav tsum tau ua ua ntej machining.Vim yog qhov tsis zoo ntawm cov khoom ua haujlwm, kev sib tsoo thiab kev ua haujlwm zoo yuav tsum tau nqa tawm thaum lub sijhawm machining txheej txheem los txhim kho qhov tseeb ntawm machining.Hom kev ua haujlwm ntawm piston pas nrig yog reciprocating linear motion.Txhawm rau txhim kho lub neej kev pabcuam ntawm tus pas nrig piston, qhov saum npoo yuav tsum yog chrome-plated los txhim kho nws qhov tawv tawv thiab hnav tsis kam.Tom qab chrome plating, polishing kev kho mob yuav tsum tau ua kom tau zoo dua nto roughness, txo kev sib txhuam, thiab txhim kho kev sib khi.Txij li cov txheej txheem polishing yuav luag tsis cuam tshuam rau sab nraud ntawm lub piston pas nrig, lub workpiece yuav tsum tau ua kom tiav qhov siab dua qhov roughness ua ntej chrome plating.Yog li ntawd, nws yog ib qho tsim nyog yuav tsum tau ntxiv cov txheej txheem sib tsoo ua ntej txheej txheem chrome plating (kev sib tsoo zoo kuj tuaj yeem txhim kho qhov adhesion ntawm chromium. ).Raws li cov kev soj ntsuam saum toj no, cov txheej txheem tsim nyog ntau dua rau cov pas nrig piston yog: straightening-rough turning-fine turning-fine grinding-chrome plating-polishing.

Q6: Dab tsi yog qhov polishing ntawm pneumatic lub tog raj kheej piston pas nrig

A: Thaum lub sij hawm tig, qhov chaw nruab nrab uas ua lub luag haujlwm ntawm qhov chaw yuav qhia tau qee qhov kev hnav.Txhawm rau kom ntseeg tau cov ntsiab lus sib koom ua ke ntawm cov qauv ntsuas, lub qhov nruab nrab yuav tsum tau muab txiav ua ntej sib tsoo kom ntseeg tau tias kev ua haujlwm zoo.Thaum sib tsoo, kev sib tsoo yuav tsum tau nqa tawm ntawm lub voj voog sab nraud nyob ze ntawm qhov kawg ua ntej, thiab kev sib tsoo ntawm tus pas nrig piston tuaj yeem nqa tawm tsuas yog thaum qhov kev sib tsoo ua tau raws li qhov yuav tsum tau ua.Ntxiv nrog rau kev txhim kho qhov tseeb qhov tseeb, cov txheej txheem sib tsoo zoo kuj yuav tsum tau txais qhov siab dua qhov roughness ntawm lub tshuab ua kom zoo dua qub los txhim kho kev sib raug zoo ntawm chromium ions thaum lub sij hawm electroplating txheej txheem.Txhawm rau kom ntseeg tau tias lub thickness ntawm chromium plating txheej ntawm lub piston pas nrig kawg yog ib yam, lub nto roughness tom qab kev sib tsoo zoo yuav tsum nyob ze rau ntawm qhov chaw roughness tom qab chromium plating thiab polishing.Yog hais tias qhov roughness ntawm lub piston pas nrig yuav tsum siab, xws li Ra <0.2 μm, nws yuav tsum tau finely av.Ntxiv super zoo sib tsoo los yog polishing txheej txheem tom qab sib tsoo.